Technical Features

●Size: 1.5"-4",DN40-DN100

●Material: 304/1.4301, 316L/1.4404, ASME BPE 316L 1.4435 NB2 Fe≤0.5%

●Pressure: vacuum to 10bar (1.0 MPa)

●Temperature: EPDM -20 ℃ to +130℃, Depending on the seal material

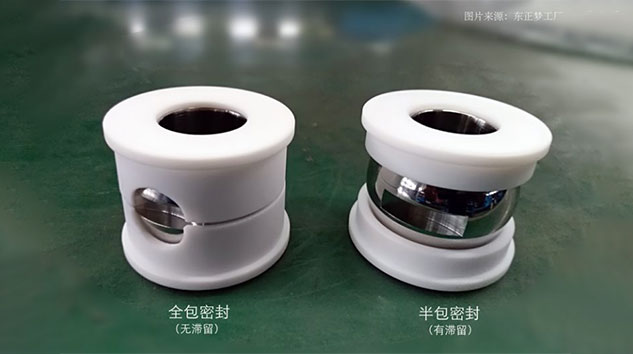

●Seal: EPDM SILICON FKM FFKM HNBR FVMQ NBR

●Connection standard: DIN SMS ISO IDF RJT BS4825 ASME BPE 3A DIN11864 DIN11853

●Connection method: thread clamp, welding, flange

●Drive mode: manual, pneumatic.

●Surface: Ra≤0.8μm; MP=Ra≤0.3μm; EP=Ra≤0.3μm

●Certification: FDA 177.2600; 3A-18-03; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC