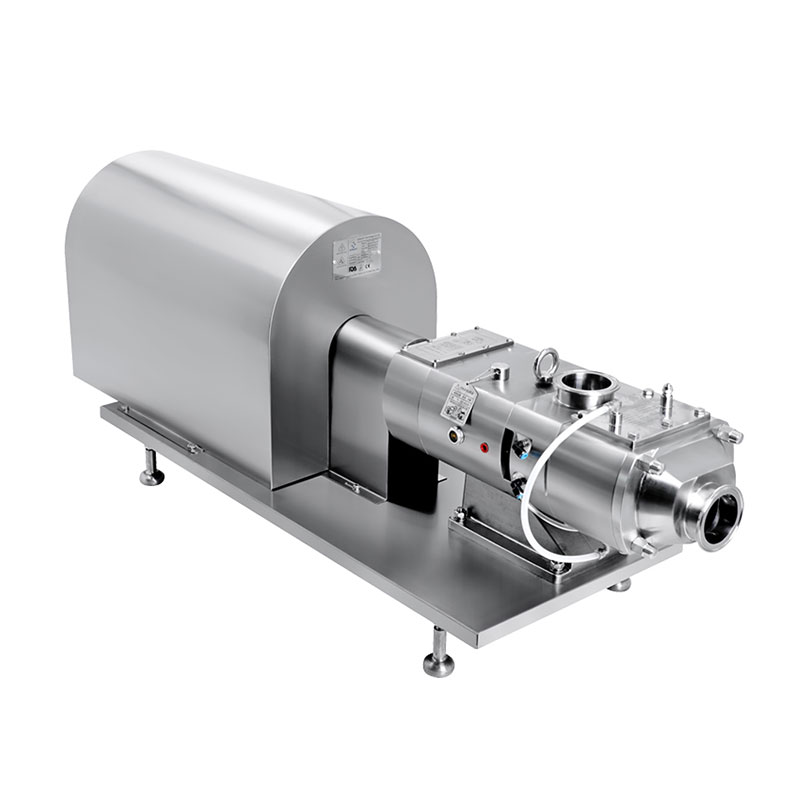

Twin screw pumps are positive displacement pumps that utilize two intermeshing screws to move fluids. Renowned for their versatility, efficiency, and ability to handle a wide range of fluids, they are widely employed across various industries. This article delves into the working principle, advantages, and applications of twin screw pumps.

The core components of a twin screw pump are two parallel screws that rotate in opposite directions within a closely fitted casing. As the screws rotate, they create sealed chambers between the screw threads and the casing walls. These chambers progressively move from the suction side to the discharge side of the pump, trapping and transporting the fluid.

The key to the pump's operation lies in the precise design of the screws and the minimal clearance between the screws and the casing. This design ensures that the fluid is effectively sealed within the chambers, preventing backflow and enabling the pump to generate high pressures.

Twin screw pumps offer several advantages over other types of pumps:

1.Versatility: They can handle a wide range of fluids, including viscous, abrasive, and shear-sensitive liquids, as well as those containing solids or gases.

2.Efficiency:Twin screw pumps are highly efficient, even when handling viscous fluids, due to their positive displacement design and minimal internal slippage.

3.Smooth Flow: The continuous displacement of fluid by the rotating screws results in a pulsation-free flow, making them ideal for applications requiring a steady flow rate.

4.Self-Priming: Twin screw pumps are self-priming, meaning they can evacuate air from the suction line and start pumping without the need for external priming.

5.Low Shear: The gentle pumping action of twin screw pumps minimizes shear forces, making them suitable for handling delicate fluids that can be damaged by high shear rates.

6.High Pressure Capability:Twin screw pumps can generate high discharge pressures, making them suitable for demanding applications.

III.Applications of Twin Screw Pumps

The versatility and reliability of twin screw pumps make them suitable for a wide range of applications across various industries, including:

1.Oil and Gas:Transferring crude oil, refined products, and drilling fluids.

2.Chemical Processing: Handling a wide range of chemicals, including acids, solvents, and polymers.

3.Food and Beverage: Pumping viscous food products, such as chocolate, syrup, and dough.

4.Marine: Fuel transfer, cargo handling, and ballast operations.

5.Power Generation: Lubrication oil circulation and fuel oil transfer.

6.Wastewater Treatment: Sludge and biosolids handling.

Twin screw pumps are highly efficient and versatile positive displacement pumps that offer numerous advantages for handling a wide range of fluids. Their ability to handle viscous, abrasive, and shear-sensitive liquids, coupled with their smooth flow and high-pressure capabilities, makes them indispensable in various industries.

DONJOY's highly professional products and technologies are widely used in biopharmaceuticals, semiconductors, new energy, food, beverages, alcohol, fine chemicals and other fields. If you are not sure how to choose Twin Screw Pumps, there are many models available on the website. If you need more parameters or technical questions, please contact us and our professional technicians will answer you online.

According to ASME BPE, EHEDG, FDA and 3A standard, DONJOY got certificates of PED-97/23/EC and MD-06/42/EC issued by TUV, ……