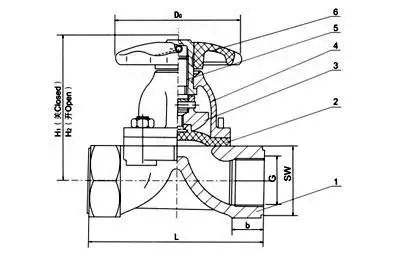

Diaphragm valve is a clamping valve, which is mainly used for opening and closing on the pipeline. To be precise, a diaphragm valve is a globe valve that uses a diaphragm as an opening and closing member to close the flow channel, cut off the fluid, and separate the valve body cavity from the valve cover cavity. Diaphragms are usually made of elastic, corrosion-resistant, impermeable materials such as rubber and plastic. The valve body is mostly made of plastic, glass fiber reinforced plastic, ceramic or metal rubber-lined material.

1. The valve does not need a separate valve stem packing and sealing structure. The diaphragm plays a role in sealing the valve stem while cutting off the medium.

2. The highly flexible diaphragm can be closed reliably, and even the dirty liquid can be cut off well. Therefore, the operating mechanism and the medium channel are completely separated, so that the diaphragm valve is not only suitable for the food industry and the medical and health industry, but also for some difficult-to-transport media and more dangerous media.

Usually, diaphragm valve is recommended for use conditions or when strict sealing performance, mud medium, wear, light structure, low pressure cut-off (small pressure difference) leakage to the atmosphere, and abrasive medium are required. Diaphragm valves can be used in the occasions of two-position adjustment, throttling, channel constriction, low noise, cavitation and vaporization, and small operating torque. Under the conditions of high temperature medium, high pressure medium, high pressure cut-off (large pressure difference), fast opening and closing action, and short structure length, diaphragm valves are not selected, except for metal diaphragm valves.

The structural feature of the metal diaphragm valve is that a group of thin hemispherical metal films are clamped in the valve body as a barrier between the valve stem and the fluid. Valve closing is achieved by pressing the valve disc against the valve seat by the stem tip and metal film. The valve is opened by an internal spring, and when the valve stem is raised and out of contact with the diaphragm, the valve disc is raised. Since the stroke of the valve is equal to the stroke of the diaphragm, the characteristic lift of this valve is much smaller than that of ordinary valves.

In order to overcome the resistance loss caused by the low lift, the valve seat and flow area are larger than the general valve, in order to obtain a larger flow. Due to the larger valve seat of this valve, the force is much higher than that of the usual valve in order to obtain sufficient sealing force on the valve disc because there is no direct contact between the valve stem and the valve disc. The valve disc will not pass the valve stem to make it off the valve seat, so this valve is suitable for one-way flow with differential pressure, and usually the medium is from "below the valve seat". However, a large amount of backflow should be avoided in use, so as not to affect the closing of the valve. Generally speaking, it is economical and effective to use metal diaphragm valves under high temperature and high pressure; diaphragm valves can also be used in low temperature and low pressure applications where synthetic rubber diaphragm valves are not expected.

Donjoy's new development of big mixing proof valve are on the market!

The Main Areas of Application for Sanitary Centrifugal Pumps

Twin Screw Pumps: A Comprehensive Guide to Their Working Principle and Applications

MINI Rotary Lobe Pump with Servo Motor: Revolutionizing Hygienic Pumping Solutions

According to ASME BPE, EHEDG, FDA and 3A standard, DONJOY got certificates of PED-97/23/EC and MD-06/42/EC issued by TUV, ……